During the design process the underlying goal is to optimize the desirable properties while minimizing any undesirable properties. To some extent, this often ends in a compromise, but one that meets or exceeds the requirements dictated by the application.

Our Process

The list below illustrates a simplified timeline of a typical project's development.

1. Address the application of the part that is to be manufactured

2. Prioritize the physical properties necessary for the project

3. Development of a suitable material

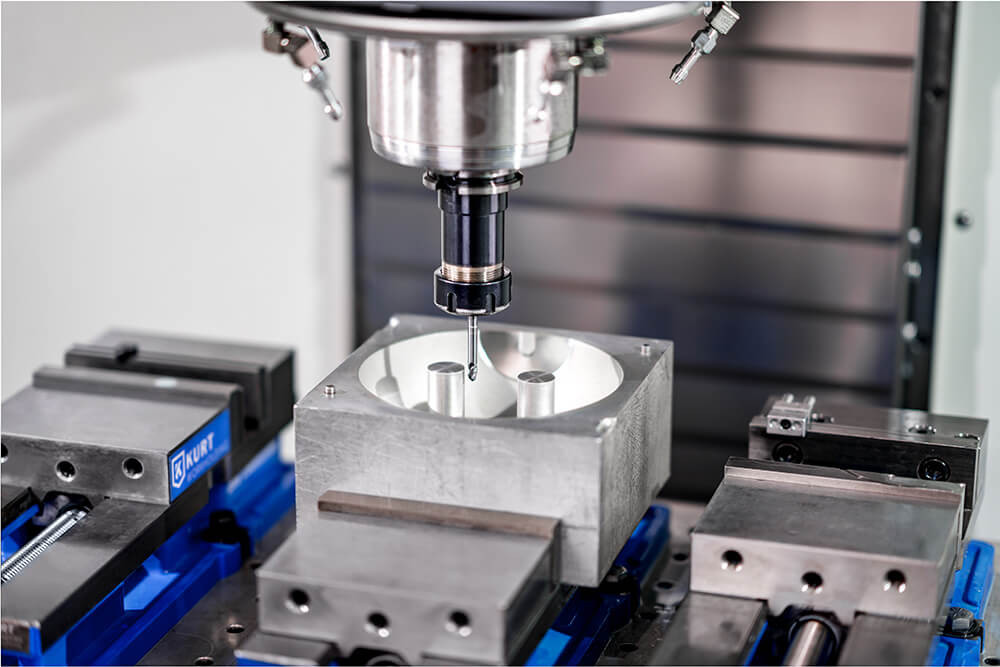

4. Tooling design

5. Prototype part

6. Testing of prototype

7. Revisions if any to design or material

8. Production

Our Quality Guarantee

Once a part is created, it is inspected for flaws and weaknesses. If any faults are exposed, they will be addressed and the tooling or formulation altered accordingly.

FallLine employs highly skilled and experienced chemists and engineers who are experts in the field of polyurethane. They will tirelessly endeavor to ensure that your polyurethane project is a success.