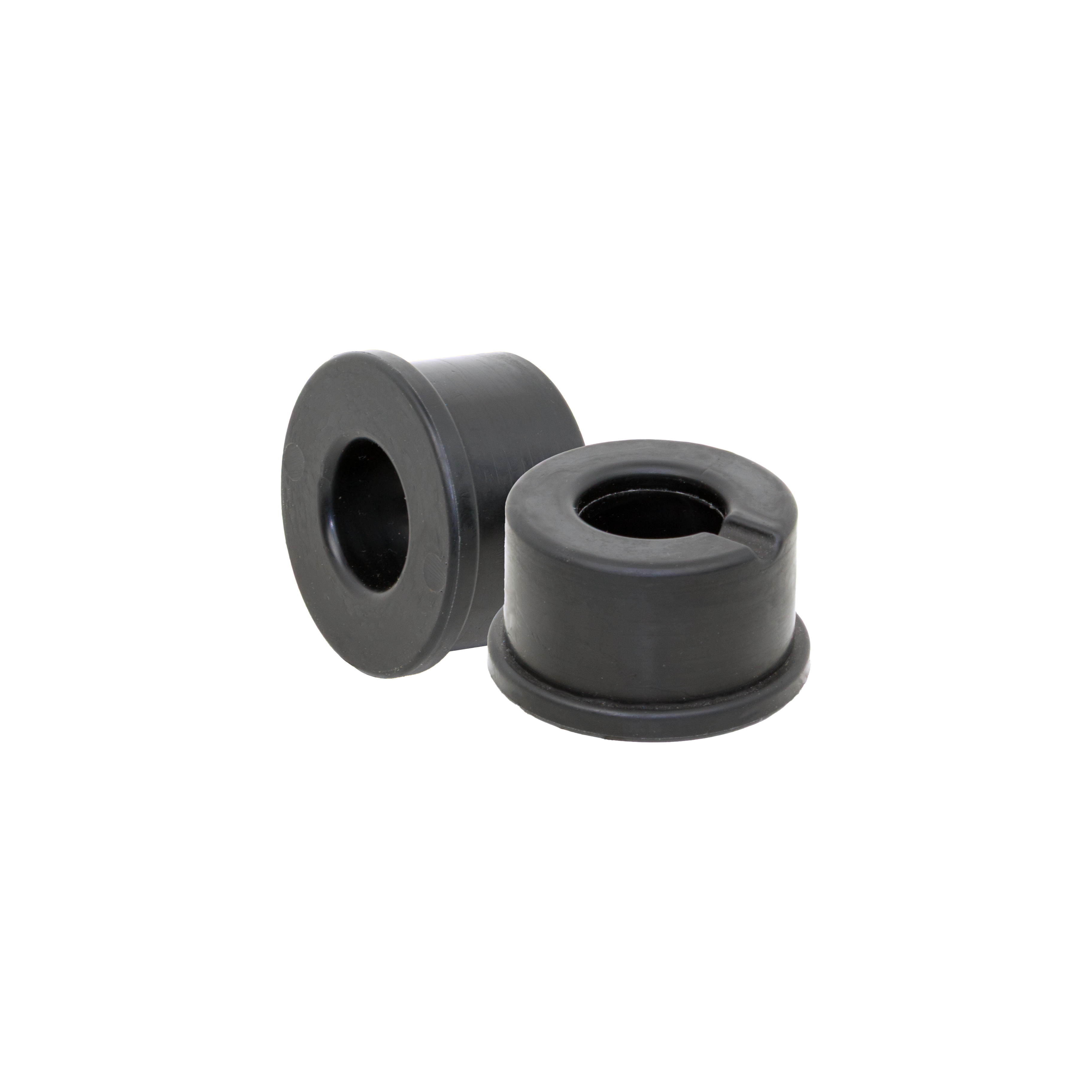

FallLine manufactures high-performance polyurethane bushings for applications that demand precision, flexibility, and wear resistance. We offer a wide range of durometers and formulations to create custom urethane bushings based on your specific drawings and specifications. OEMs rely on FallLine to produce custom polyurethane bushings where performance and consistency are essential.

Built to Absorb, Engineered to Last

Polyurethane bushings manage motion by isolating vibration and reducing friction between moving parts. They retain structural form under pressure and handle prolonged mechanical stress in high-load environments.

FallLine employs proprietary molding methods to ensure consistent results in the manufacturing process.

Precision-Molded Urethane Bushings for Demanding Environments

Custom urethane bushings transfer force, absorb impact, and control movement in mechanical assemblies. They work to keep components aligned and reduce metal-to-metal contact.

FallLine proudly manufactures custom precision-molded polyurethane bushings that do the following:

- Absorb shock and reduce vibration

- Resist wear under continuous load

- Maintain compression strength across temperature shifts

These bushings improve mechanical performance in systems that require stable, repeatable motion under stress.

REQUEST A QUOTE TODAYWhy Choose Polyurethane Bushings Over Alternative Materials

Unlike rubber or plastic, polyurethane allows for fine-tuned durometer selection and custom-tailored formulations to ensure optimal performance in your specific application.

Custom urethane bushings support longer service intervals and more consistent mechanical behavior across various industrial applications, particularly where legacy materials deform, swell, or degrade over time.

REQUEST A QUOTE TODAYApplications and Industries That Rely on Custom Polyurethane Bushings

Custom polyurethane bushings support equipment in various industries, including snow removal, agriculture, construction, material handling, and automotive, where moving components are subject to constant abuse.

High-quality polyurethane bushings are essential for the reliable performance of demanding equipment and vehicles.

Below are some of the most common applications of these custom polyurethane bushings:

- Pivot points in suspension or lift systems

- Load-bearing joints in industrial machinery

- Isolated mounting systems in technical equipment

FallLine proudly manufactures custom urethane bushings for these environments and many others, and we’re here to help you get the reliability you’ve been seeking.

Contact us now for a custom order.

Get in touch to request a quote and confidently move forward with your urethane or custom polyurethane rollers.

Get in touch to request a quote and confidently move forward with your polyurethane bushings or custom urethane bushings.

We proudly help manage tooling internally, which cuts lead times and limits production risk overall. With FallLine, engineers get clear answers, fast prototypes, and repeatable, dependable results.

REQUEST A QUOTE TODAYFrequently Asked Questions About Polyurethane Bushings

Learn more about polyurethane and urethane bushings through our frequently asked questions.

Polyurethane bushings provide longer service life, more consistent performance, and better resistance to chemical exposure and environmental wear than rubber or plastic.

Yes! FallLine manufactures custom urethane bushings according to the part geometry, performance specifications, and material requirements you provide.

In many applications, polyurethane bushings function without added lubrication due to their low friction properties, though it depends on the system’s design.

Yes. FallLine specializes in volume production of custom urethane bushings, with tooling and capacity to support consistent quality across large runs.